The harsh climate of the UAE presents unique challenges for construction and engineering projects. With high humidity, salt-laden air from the Gulf, and extreme temperature fluctuations, standard fastening solutions often fail prematurely due to corrosion. In such demanding environments, galvanized through bolts and anchors have emerged as the preferred choice for professionals seeking reliable, long-lasting fastening solutions.

Galvanization involves coating steel or iron with a protective layer of zinc. When galvanized through bolts and anchors are exposed to the atmosphere, the zinc forms zinc oxide, which further reacts with carbon dioxide to create zinc carbonate. This stable, non-reactive layer adheres firmly to the metal beneath, shielding it from moisture and other corrosive elements.

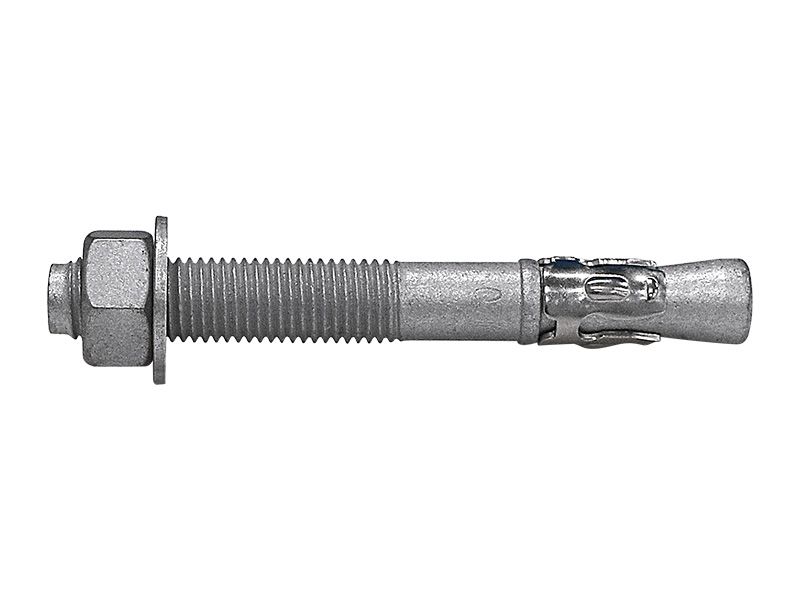

The zinc coating on Galvanized Through Bolts serves as a sacrificial anode. Even when the coating is scratched or damaged, the surrounding zinc corrodes preferentially, protecting the underlying steel. For UAE construction projects, this self-healing property proves invaluable, especially in coastal areas where salt exposure accelerates metal deterioration.

Two primary galvanization methods are commonly used for producing galvanized through bolts and anchors. Hot-dip galvanization involves immersing bolts in molten zinc at approximately 450°C, creating a thick, durable coating that typically exceeds 45 microns. Electrogalvanization, on the other hand, uses an electroplating process to deposit a thinner zinc layer.

For UAE applications, hot-dip galvanized bolts generally provide superior protection due to their thicker coating. Construction firms working on coastal developments, marine structures, or outdoor installations typically specify hot-dip galvanized fasteners to ensure maximum corrosion resistance and service life.

Widely used in the expanding construction industry in the United Arab Emirates, galvanized through bolts and anchors. Major infrastructure projects utilize these corrosion-resistant fasteners for securing steel structures, anchoring heavy equipment, and fastening precast concrete elements. The Dubai Metro, Burj Khalifa, and numerous bridges across the Emirates rely on galvanized bolts to maintain structural integrity despite environmental challenges.

Renewable energy installations, particularly solar farms in desert locations, depend on galvanized bolts to secure panel mounting systems against corrosion and intense UV exposure. The oil and gas industry similarly relies on these fasteners for outdoor equipment and infrastructure that must withstand both corrosive chemicals and harsh environmental conditions.

While corrosion protection remains the primary advantage of galvanized bolts and anchors, their benefits extend beyond longevity. The zinc coating provides excellent abrasion resistance, preventing damage during installation and operation. Galvanization also eliminates the need for painting or regular maintenance, reducing lifetime project costs significantly.

Engineers appreciate that galvanized through bolts maintain consistent performance across temperature extremes common in the UAE, where surface temperatures can exceed 70°C in summer and drop substantially during winter nights. The coating’s durability ensures fastening integrity throughout these fluctuations.

As UAE construction continues to push boundaries with ambitious projects in challenging environments, galvanized through bolts and anchors remain fundamental to achieving structural durability and safety. Their proven performance in corrosive conditions, coupled with minimal maintenance requirements, makes them indispensable for engineers and contractors committed to building structures that stand the test of time.